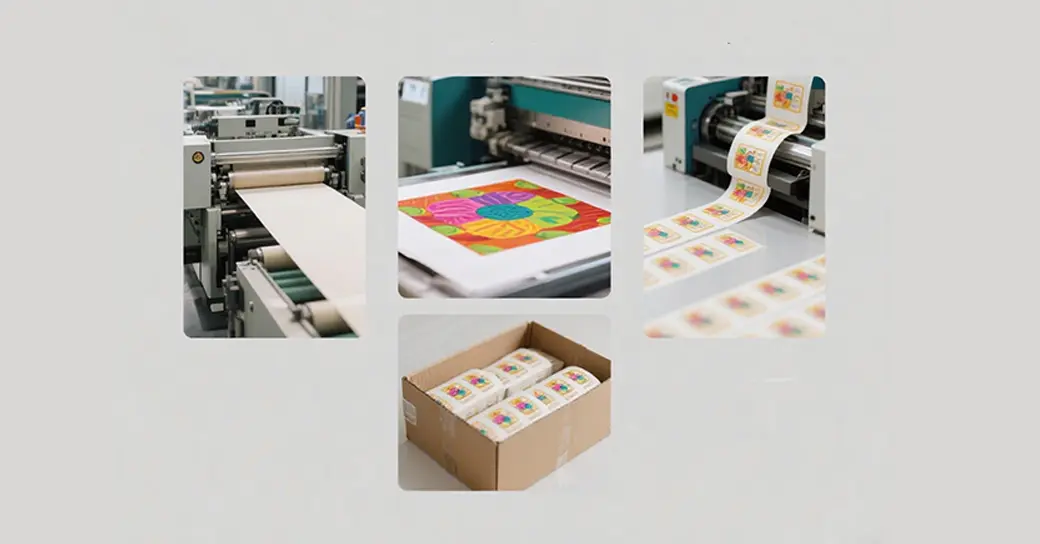

The production process of label printing

Demand Analysis and Design: The process begins with comprehensive communication between the manufacturer and the customer. This dialogue aims to clarify essential aspects such as the size, shape, material, and specific anti-counterfeiting technology requirements of the label. Once these requirements are established, designers create a visual representation that not only meets aesthetic standards but also facilitates easy identification of authenticity. It is important for customers to provide proof of brand authorization to ensure that the design adheres to legal and branding guidelines.

Proofing: After finalizing the design, the project moves into the plate-making stage. This step is crucial, as it involves careful consideration of the label's material and the desired printing effect to ensure that the layout is accurate and ready for production. Once the plates are made, a proofing process is conducted. This allows the enterprise to evaluate whether the printing effect aligns with the agreed-upon specifications and quality standards, providing an opportunity for any necessary adjustments before full production.

Printing: The actual printing phase employs advanced printing equipment, such as digital printing presses or multi-color offset printing machines. During this stage, the anti-counterfeiting designs and textual elements are printed onto the label material. It is vital to maintain strict control over printing parameters, including ink levels and color clarity, to achieve consistent quality throughout the production run. Attention to detail during this phase directly impacts the final product's visual appeal and functionality.

Post-Processing Treatment: Once printing is completed, the labels undergo various post-processing treatments, which may include lamination, hot stamping, and cutting. These processes are essential for enhancing the durability and anti-counterfeiting capabilities of the labels. Lamination provides a protective layer, increasing gloss and abrasion resistance, while hot stamping adds a visually striking element that can elevate the label's overall appeal, making it more attractive to consumers.

Quality Inspection and Packaging: The final step in the label production process involves rigorous quality inspection of the finished products. Each label is assessed for accuracy, color fidelity, and overall quality to ensure it meets both customer expectations and industry standards. After passing inspection, the labels are carefully packaged for delivery, ensuring they arrive in pristine condition and ready for application.

By meticulously following these steps, manufacturers can produce high-quality labels that not only fulfill functional requirements but also enhance brand image and consumer trust.